About

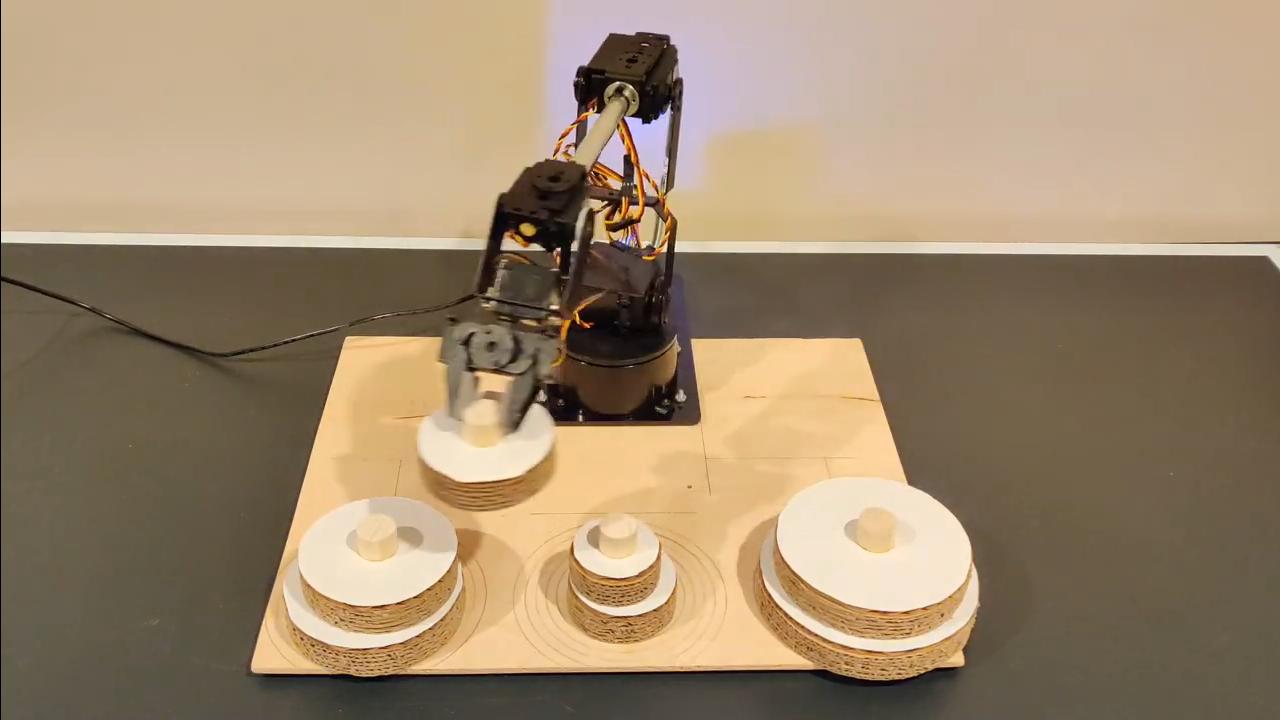

I have a passion for designing, making, and solving problems. Starting with Legos and progressing to robots and racecars, I'm excited to see where this passion will take me!

Engineer & Designer

- Birthday: 27 September 1996

- City: Penfield, New York, USA

- Age: 21

- Degree: Bachelor of Science in Mechanical Engineering

- Email: deanandrewrogers@gmail.com

Skills

Resume

Download a PDF version here.

Summary

Dean Rogers

Robotics Engineer bringing a deep understanding of the technical aspects of robotics, including motion control, sensor integration, and programming, along with eight years in the manufacturing sector. Devoted to ongoing learning and primed to make a significant contribution quickly.

- Penfield, New York

- deanandrewrogers@gmail.com

Education

Bachelor of Science in Mechanical Engineering

Sep 2015 - May 2022

University of North Dakota, Grand Forks, North Dakota

- Magna Cum Laude (GPA 3.83/4.00)

- Formula SAE Team Member

- Completed while working full-time

Professional Development

Courses

- Robotics Software Engineer Nanodegree | Udacity

- Anticipated, 2/2025

- C++ for Programmers | Udacity

- Anticipated, 1/2025

Certifications

- Six Sigma Green Belt | Abacus | Rochester, NY

- 2016

- APICS Certified Supply Chain Professional (CSCP)

- 2015 - 2020

Professional Experience

INVENTORY BUSINESS INTELLIGENCE SPECIALIST/PROCUREMENT SPECIALIST

May 2018 - Present

Ranger Design, Rochester, New York

Promoted to partner with production leaders in Rochester and Montreal to make shipment decisions, communicate supply chain issues and risks, monitor stock-out counts, and ensure timely replenishment of goods. Collaborate with internal and external customers on inventory audits and ensure data integrity. Identify and implement inventory cost reduction initiatives.

- Expanded Business: Contributed to company's growth, from $50M to $100M in seven years, serving as Supply Chain Customization and Development lead.

- Stepped up to lead project and fast-tracked deployment, completing in just one year

- Mapped supply chain processes, unraveled new ERP system, and tested, developed, and trained ten team members on use.

- Enhanced Operations: Drove business alignment by managing and building visual display system used by production team.

- Built an Ubuntu server-based LAMP stack and utilized Python scripts to integrate data from ERP and Excel. HTML, CSS, and PHP codes were modified as needed.

- Averted Risks: Used safety stock, minimum quantities, and forecasting models when purchasing materials. Calculation methods were researched and improved, including the segregation of demand from different business areas for independent analysis.

- Accuracy: Developed method of separating distribution and fleet demand forecasting processes.

- Reduced Errors & Lightened Workload: Developed and implemented system to automate transfer orders between Rochester and Montreal manufacturing locations.

- Tasked with Technical Training: Developed training program that taught VBA code for Excel and SQL resulting in improved data access, automation, and workflows.

- Stayed Resourceful: Helped company remain competitive despite global Covid-19 supply chain disruption. Embodied "we find a way" motto by extensively planning orders and tirelessly working to secure suppliers and transportation options.

PROCUREMENT SPECIALIST

Mar 2015 - May 2018

Ranger Design, Rochester, New York

Managed sourcing, planning, quoting, scheduling, and ordering materials. Maintained strong relationships with suppliers, communicating with internal teams on project timelines and deadlines, and ensuring commitments were met.

- Optimized Processes: Removed inefficiencies and improved quality of information shared by developing a shortage dashboard tool harnessing rapid and real-time communication and minimizing late orders.

- Developed in Excel, integrated into MS Access, and later incorporated into a new ERP system.

- Learned how to customize C# .NET system and build as native tool in ERP.

- Continued to be a crucial part of procurement - used daily by team and leadership in Rochester and Montreal.

- Minimized Costs: Responded to potential stock shortages caused by volatile supply and demand by creating early warning tools in Excel and Epicor.

- Strengthened Performance: Created Epicor tool to measure quantifiable goals and document progress and completion of procurement KPIs.

- Shared Knowledge: Commended for technical proficiency and ERP knowledge, as well as eagerness to share expertise in SQL and Excel VBA.

PRODUCTION ASSOCIATE

Sep 2014 - Mar 2015

Ranger Design, Rochester, New York

Created and assembled ladder racks, shelving, drawers, and safety partitions. Cut and measured materials, using hand and power tools, and followed blueprints and specifications to ensure units met quality and safety standards. Packaged finished products and prepared them for shipment.

- Increased Output: Continually sought ways to improve production processes and improve efficiency.

- Exceeded Targets: Consistently outpaced performance goals.

Contact

Please feel free to reach out to me for any questions, additional details, or references.